Table of Content

A digital twin is a computer-generated replica of a physical object or system. This digital copy accurately models a real-world entity, such as a wind turbine or an entire city, and allows for the simulation and analysis of its physical behavior. Although the concept of digital twins has existed for several decades, advancements in technology, such as the Internet of Things (IoT), artificial intelligence (AI), and cloud computing, have enabled the creation of highly detailed and precise digital twins that were not possible before.

These digital representations can be used for a wide range of applications, from predicting equipment failures in manufacturing to optimizing energy consumption.

The use of thid is growing and is poised to significantly impact many industries in the years to come. This article will explore the concept of digital twins, their use cases, and the benefits they offer.

What is a digital twin and how does it work?

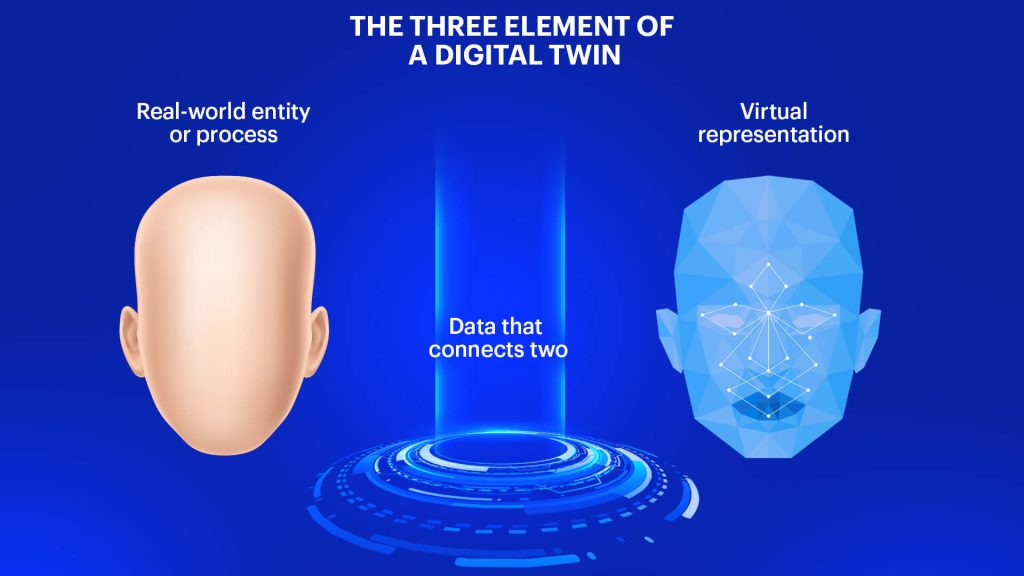

This refer to computer-generated replicas of physical assets, products, or These computer-generated systems can simulate, analyze, and improve the performance of their real-world counterparts. This concept typically involves the following three elements:

- A physical entity

- The digital version of the said entity

- The data link which connects both

These are made in a way that they can communicate with various sensors on the physical entity, allowing them to accurately portray real-world conditions. Hence, they are not generic and contain characteristics that make each twin unique, just like its physical counterpart.

Another critical fact to note is that there is a difference between simulations and digital twins. A simulation imitates a specific process or operation using a mathematical model. Therefore, it is only present during one phase of the product lifecycle. At the same time, digital twins are present throughout the lifecycle and can be used for monitoring, prediction, and control purposes.

IoT (Internet of Things) devices play a crucial role in digital twins, providing real-time data for the digital twin to emulate the physical counterpart. As IoT devices are refined and enhanced further, the quality of data sent to the digital twin increases, which allows for better optimization of the physical entity. On the other hand, digital twins bring structure and usability to IOT data which is often hard to interpret, forming a symbiotic relationship between the two.

They are created using IOT devices’ data, combined with conceptual models such as CAD. Once properly integrated, they can run various simulations and gain actionable insight, which can be used to optimize the physical entity.1

Types of digital twins

Digital twins are modular, and it is common to have several types of digital twins exist within one complex system. According to the hierarchy with which they are deployed, we can classify them as follows:

- Component twins (part twins) – The most basic unit and smallest functioning component

- Asset twins – Two or more components whose interaction is represented in the digital twin.

- System twins (unit twins) – Assets assembled into a complete, functioning system.

- Process twins – Systems working together to create an entire process.2

Exploring the Benefits of Implementing a digital twin strategy

Digital twins offer a real-time look at what is happening with physical assets. Implementing a digital twin strategy can bring several benefits to an organization, including:

- Cost-effective R&D – They can replace expensive physical prototypes while providing more data that will give valuable insights before starting production.

- Improved efficiency – Organisations can analyze and optimize their operations in real-time by creating a digital replica of physical assets and processes, improving efficiency and reducing downtime.

- Enhanced decision-making – They can provide real-time data and insights, allowing organizations to make data-driven decisions and respond quickly to environmental changes.

- Predictive maintenance – They can monitor physical assets and identify potential problems, enabling organizations to perform maintenance before any breakdown occurs. This proactive approach minimizes downtime and reduces associated costs.

- Increased flexibility -They allow organizations to simulate different scenarios, evaluate the impact of changes, and make decisions before implementing them in the physical world, increasing flexibility and reducing risk.

- Improved Customer Satisfaction – By providing customers with real-time information and insights, digital twins can enhance customer engagement and satisfaction.

Implementing a digital twin strategy can help organizations improve their operations, make better decisions, and increase customer satisfaction.

The Challenges & Risks of Using Digital Twins

The use of digital twins in various industries comes with both challenges and risks that need to be considered and addressed.

- Challenges

- Data Integration: It can be difficult to integrate data from various sources and ensure its accuracy.

- Data Privacy: Digital twins may contain sensitive data that needs to be protected.

- Technical Complexity: Creating and maintaining digital twins requires specialized skills and technology.

- Cost: The cost of developing and implementing digital twins can be high.

- Risks

- Security: Digital twins may be vulnerable to hacking, cyberattacks, and data breaches.

- Reliability: The accuracy and reliability of digital twin models may be impacted by errors or inaccuracies in the data used to build them.

- Compliance: Ensuring that digital twins comply with relevant regulations and standards can be challenging.

- Liability: Using digital twins in critical systems and decision-making may raise liability concerns.

It is important to carefully assess the benefits and risks of using digital twins and to implement appropriate measures to minimize risks and maximize benefits.

Real-world use cases for digital twins in different industries

- Automotive

- The automotive industry utilizes digital twins to simulate new designs and concepts, providing valuable insights into their performance before they are physically constructed. This approach enables stakeholders to gain a better understanding of the potential outcomes of a particular idea. Further, real-time data from existing vehicles will provide data portraying the vehicle’s current state to perform repairs before reaching failure.

- Volvo has recently stepped up its presence in the digital twin space by introducing this technology in various parts of its business, from prototyping to creating a more immersive buying experience.

- Manufacturing

- This is the area in which the use of digital twins has gone along the furthest. Digital twins can simulate and optimize the entire production process, which includes designing and testing new products, evaluating assembly line efficiency, and predicting maintenance needs. This approach helps organizations identify potential issues and inefficiencies and optimize their processes for maximum performance and profitability.

- Siemens, the German multinational conglomerate, has adopted digital twins in an approach to cover the entire lifecycle of assets, from their design and production to operation, servicing, and maintenance.

- Utilities and energy

- In the energy industry, digital twins can model and optimize power plants, wind farms, and other energy-generating assets to improve efficiency and reduce costs. These systems can also assist in transforming job-critical training into interactive VR (Virtual Reality) environments.

- The renewable energy company GE has experienced efficiency gains of up to 20% in their wind farms through digital twins.

- Disaster management

- The effects of global climate change have recently been felt all over the world. Digital twins can help to mitigate these effects by allowing for the intelligent design of more innovative infrastructures, emergency response plans, and climate change monitoring.

- By making digital twins of cities, disaster management efforts can be coordinated more effectively, reducing the loss of life and property. The Shanghai digital twin is an excellent example.

- Retail and e-commerce

- In retail, digital twins can be used to model and optimize store layouts and product displays, helping to improve the customer experience and increase sales. Companies have also started using this technology to build online twins of their stores to enhance their online presence.

- Fashion retailers such as H&M and Zara have adopted digital twins to improve their presence in the online space and gain market share, while e-commerce brands like Amazon and eBay use this technology to help customers better visualize products. 3

- Aerospace

- Designing and manufacturing products like aircraft and spacecraft are so expensive that it is crucial to complete tasks accurately first to prevent costly delays. Digital twins enhance decision-making by enabling teams to visualize and interact with computer-aided design (CAD) models and other datasets in real-time 3D, from design and engineering to assembly and maintenance.

- Boeing has recently introduced an AR(Augmented Reality) powered digital twin to assist in aircraft inspection. 4

- Healthcare

- In healthcare, digital twins can model the human body and simulate medical procedures, such as surgeries and drug treatments, to improve patient outcomes. Systems have also modeled the flow of people through hospitals and tracked where infections may exist and who may be in danger through contact.

- French startup NUREA is developing an AI-based digital twin imaging software to assist cardiovascular surgeons. Another exciting project is done by US-based startup Q Bio, which is building a whole-body digital twin platform called Q BIO Gemini. 5

The digital twin concept is revolutionizing the business world by combining artificial intelligence (AI), the Internet of Things (IoT), and data analytics, resulting in limitless potential and significantly enhanced business value.6

Conclusion

Digital twins have truly revolutionized product development and operations management. Their impact has transformed how we handle these domains, paving the way for more efficient and effective processes.

Organizations can simulate and analyze real-world scenarios in a controlled environment by utilizing the capability to create virtual representations of physical assets and systems. This enables them to make better-informed decisions, minimize downtime, and enhance overall efficiency.

With the ongoing advancement of technology, it is anticipated that digital twins will become increasingly prevalent. These digital replicas offer innovative and novel solutions to address the most critical challenges modern industries face. The possibilities for utilizing digital twins are limitless, and it is clear that this technology can transform how we conduct business in the years to come.

- siemens.com: ecosystem.siemens.com[↩]

- tributech.io: tributech.io[↩]

- juststyle.nridigital.com: How digital twins are shaping the fashion industry – Just Style magazine | Issue 15 | March 2023 (nridigital.com)[↩]

- arinsider.co: Case Study: Boeing Cuts Production Time with AR – AR Insider[↩]

- startus-insights.com: 5 Top Digital Twin Solutions impacting Healthcare Providers | StartUs Insights (startus-insights.com[↩]

- unity.com: unity.com[↩]